Industrial Productivity Tools |

Gemex Applications |

Click on the picture for the Gemex electronic demonstration |

GEMEX SYSTEM

HORIZONTAL

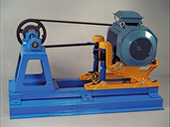

Gemex System IEC-160/180 "Horizontal"

belts for motors from 7 kW up to 25 kW.

Technical

specifications

Installation

instructions

Adjustement

instructions

|

|

|

|

|

|

| Replace belts without realignment.

duration of operation: 2 minutes

With hydraulic pump (see picture) you pump the Gemex Shelf up to the correct hydraulic pressure (see manometer on pump) f.e. 40 Bar, you lock the Gemex Cylinders with a hammer. (IPT provides a calculation of correct tension based on the configuration of your belt driven unit). This "Horizontal" unit (with 2 Gemex Cylinders) goes from IEC-200 up to IEC-425 shaft high (from 20 kW up to 500 kW) machines. |

Adjust the Belt Tension while

machine is STOPPED.

Keep the "Belt Covers" around the belts! 1. Connect the pump on the connection

nipple of the Gemex Cylinder.

maintenance timing: 2 minutes. |

Adjustment of Belt tension while

machine is RUNNING.

Do not uncover the belt cover! You can adjust the belt tension while the machine is running, you can check the belt tension without undoing the belt covers. The procedure is simple:

|

|

|

|

|

|

|

|

|

|

Technical specifications |

|

Technical specifications |

For the best function and safety we recommend that this pump is used with the Gemex system. Of course other pumps can also work if they are used with proper knowledge and care. |

|

| IPT - Maintenance Partners

Vitshoekstraat, 6 B-2070 Zwijndrecht Belgium |

tel: 32 3 800 55 85

fax: 32 3 800 55 86 gsm: 32 475 77 64 43 e-mail: john.rammeloo@maintenancepartners.com |